Interview with Helen Farr-Leander founder of Watson & Wolfe

Hi Helen, please introduce yourself and what inspired you to launch the brand Watson & Wolfe?

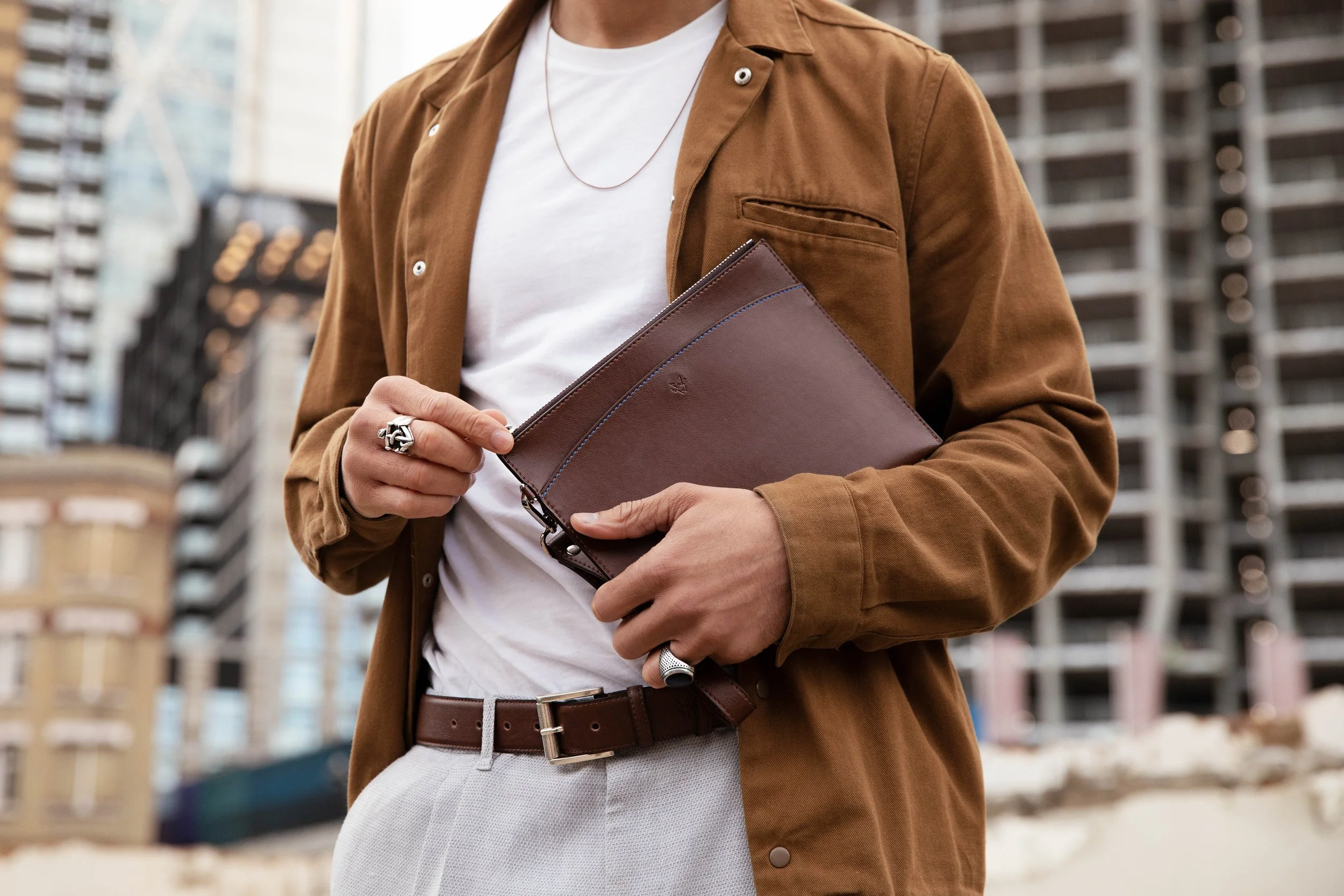

Hello everyone, my name is Helen Farr-Leander, and I am the founder of Watson & Wolfe. Watson and Wolfe began back in 2017 when I decided to start a men’s accessories brand. I had a very young family at the time and having previously worked at Aspinal of London, it felt like a very natural option for me. I was planning to make in the UK, with premium quality leather and linings, but early the following spring, my research took a turn and led me to discover the impact that leather production has on our planet. The global impact is huge and includes pollution, deforestation and unimaginably cruelty. At that moment, I knew I could no longer use leather and it drove me in the direction of alternative materials. Since then, I have myself become vegan, and now it is my passion and my mission to provide cleaner, more sustainable accessories. I initially targeted our items towards men, as I felt they were (and still are) under-represented in this sector. Due to popular demand we now also create products for everyone including women.

How hard was it to launch a brand that has put so much emphasis on sustainability?

Firstly, can I say, that I can totally understand why it is challenging for established businesses with big supply chains to change to more sustainable processes. Their whole system must change. For a start-up it is not so difficult, especially when you also opt for a slow-fashion approach. We do not release collections every season, nor do we follow trends. We will only launch an item when it is right, when we have the right materials and when we have found the right producer. All these elements must be right and fit with our demand for quality and responsibility.

Ultimately, we want our customers to own their items for as long as possible, so we produce accessories which will outlive notions of trend, that can be carried from season to season, and which are fabricated to last.

We are always aiming for total ethics fashion, which has us considering our carbon footprint just as much as the working conditions of everyone in our supply chain. Improving our supply chain with cleaner processes and better working conditions are all crucial. Sustainability in our organisation is evolving every day and each decision is made with the aim of keeping our impact low or improving a process to make it better. An example of this is our linings. In the beginning we had to compromise on the distance these travelled. The best quality we could find was in Taiwan, but that meant the rolls of fabric had to travel over 8000km to our factory in Istanbul. I was always so unhappy about that, and it took time to develop the solution. Finally, 18 months ago a lining of the same quality left a new production line just 152km from our factory. An estimate yearly saving of more than 476kg of carbon.

In 2017, we were the pioneers - the first British brand to design and make luxury, accessories for men made with next-generation materials. We are proving that it is possible - not only to produce good accessories, but to create exceptional ones.

And how much research did you have to undertake in learning about the various vegan materials?

I have a cupboard in my office which is bursting with material samples from all over the world, made with food waste, agricultural waste, and recycled materials. I love looking at and learning about all the new innovations.

Back then, we had fewer options available, but I sourced as many materials as I could find. It was important to me that we achieved the look and feel of leather. My goal was to change the perception of sustainable accessories, from one which was ‘hippyish’ to one which was cool and stylish, yet wholeheartedly traditional. It was essential that we could craft items in the same way as a leather accessory; heat score the card pockets of a wallet, personalise initials and paramount to all of this, deliver an excellent quality finish. In fact, the first material we chose, which I found in Italy, is still used in most of our core collection. It contains a minimum 30% bio plant content from non-food grade corn and is up to 3 x more environmentally friendly than animal leather. The corn content is non-GMO and from a renewable resource.

There is definitely a big learning curve, and no doubt we made mistakes in the beginning when we were sampling. But we had to test and try everything to see what performed best. Not all the materials are created equal, and not all of them can be used for every application.

Is there a difference in the performance and durability of vegan leather versus traditional leather?

Vegan leather alternatives have advanced beyond recognition in the last 5 years. The quality, durability and the creative thinking behind how they are fabricated is all done for one purpose - to provide viable alternatives to a fashion material (leather) which has the most damaging environmental footprint.

The mistake though is treating these like inferior alternatives - they are not a compromise; they are materials in their own right. As consumers we need to change our perception and not compare these against animal leather. We cannot make the fashion industry sustainable without first changing ourselves. These materials are not leather, and neither should we want them to be. Leather is the skin of an animal which has been treated with over 250 different toxic chemicals so it can last indefinitely. It does not break down in landfill easily and it leaches chemicals when it does break down. It is used in fashion like a dispensable, easily replaceable material.

The innovations in the alt leather space are doing several things. They are (generally) made using less harmful chemicals, in some cases no toxic chemicals at all, they are made with less water, less energy, less co2 and many use organic waste materials which would otherwise end up in landfill. They are durable for up to 10 years, a lifespan which already exceeds most consumers use of an item. For example, a wallet is generally replaced between 3-5 years after purchase, so why do we need to use a material which lasts longer than 5 years?

What is the design process like for you? How do you pick and work with your suppliers?

We choose our suppliers carefully because we want them to care as much as we do about the impact their businesses have on the planet. All our raw material factories harness green energy and have efficient systems for solvent and air exhaust. The effect on the surrounding environment is the lowest it could feasibly be. In terms of design and fabrication, we want to produce products which will last, so we set out to find small, artisanal factories who could deliver high quality craftsmanship, who have ethical working conditions, a fair-trade policy and who value their staff. We are fixed on working with small factories in Italy, Türkiye and Portugal, who have a long history of working with luxury leather brands. Everything is handmade by experienced people using traditional leather working techniques and our factories are incredibly supportive of our business and understand our objectives.

What is the best part of your job?

Hearing the great feedback from our customers all over the world. We have delivered to over 70 countries so far and our customers love our ethics and our collection. It is so gratifying having faced such opposition in the beginning when I announced that I wanted to create an eco, vegan brand. When I was intending to use animal leathers, nobody had anything to say about it but when I struck out in the vegan direction, I had evidently gone mad! People told me there wasn’t a demand and that men wouldn’t want sustainable, vegan products – there was so much negativity. But the opposite is true, and that discovery makes everything we do so much more important.

What projects or product lines are you currently working on?

We are very excited to announce that we are launching our first line of business bags, the Capri Satchel, and the Amalfi Laptop Briefcase. Both bags are available for pre-order until 10th September, dropping six to eight weeks later. We’ve done pre-order several times before and it works well with the ethos of slow fashion. It allows us to produce small runs to meet demand and avoid waste. These bags harness the quality of British design and the perfection of Italian craftsmanship and both bags are being made with Italian AppleSkin™. We have partnered with a small boutique factory in Florence for this capsule. It felt right that our first collection of business bags should be made in a place synonymous with quality, timeless style, design elegance and meticulous attention to detail.

Here is the link to the business bags.

https://www.watsonwolfe.com/vegan-business-bags/

Founder of this eponymous blog, focusing on men's fashion & lifestyle.